airVent Display System

The airVent Display system for the BMW E46 M3, is a system for presenting information from the E46 CAN bus on a touch screen embedded in the E46 M3 air vent console. The information is presented in various pages combining numbers, colorized bars and graphs. The main idea with the pages is that the information should be easy to read when at the race track.

The pages/Graphical User Interfaces (GUIs) included in the minimum/basic version is shown in the picture below.

Picture 1: Mosaic of GUIs delivered with the minimum/basic version

The switching between the different pages in the airVent Display is easily done by touching the screen, as well as by using the BMW E46 M3 multifunction steering wheel cruise control buttons. When cruise control is not active, the 'Cruise+' and 'Cruise-' is used to change the GUI pages. A press on the 'Resume'-button, brings up the 'Home Menu' GUI.

When in measurement mode (100-0 km/h or 0-100 km/h), the 'Cruise-' button act as Start/Initiate a new measurement, similar to tap the display in order 'This' rectangle.

By adding custom modules prepared for CAN bus data streaming, the possibility to have presentation of data beoynd the standard E46 CAN bus data is enabled. Modules for measuring oil pressure, brake pressures, gear box oil temperature, rear differential temperature and brake disc temperatures can easily be added and integrated with the airVent Display system (see all options in the webshop).

Picture 2: GUIs if adding options for OilPressure, GearBoxTemperature and DifferentialTemperature

Picture 3: Additional GUIs found in the BrakeDiscTemperature option

The airVent Display can be ordered with or without the airVent console, giving customers the opportunity to source their own console. The airVent Display hardware is installed in the airVent console by us, as well as programmed with the ordered software. As a minimum, the GUI Basic software package has to be ordered, and several options can optionally be added if needed.

Picture 4: The airVent Display installed in an E46 M3 based car.

Technical consept

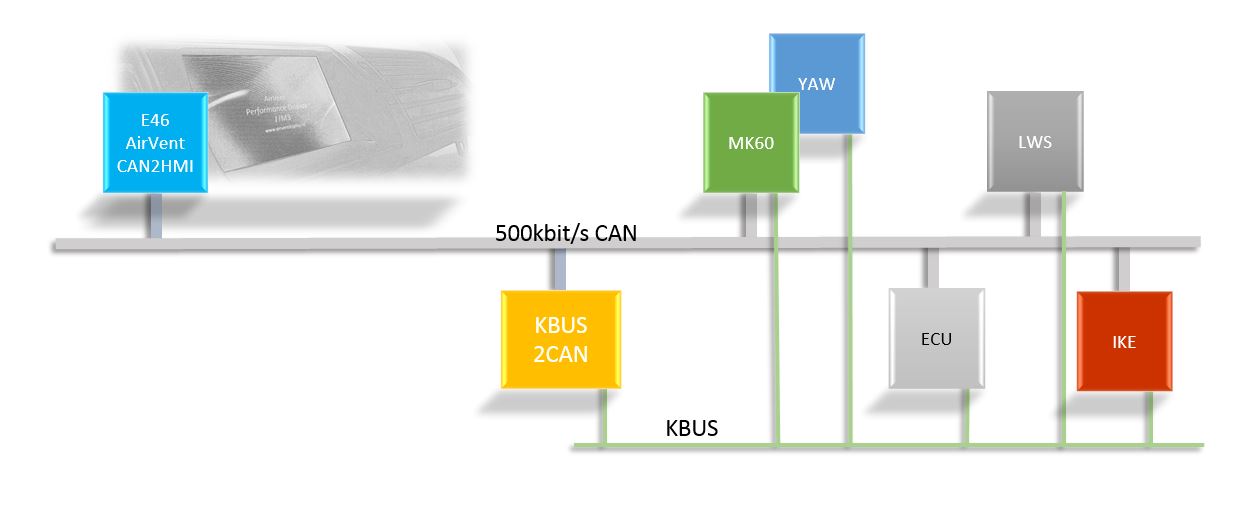

Figure 1: airVent Display, GUI Basic configuration in a Single CAN network

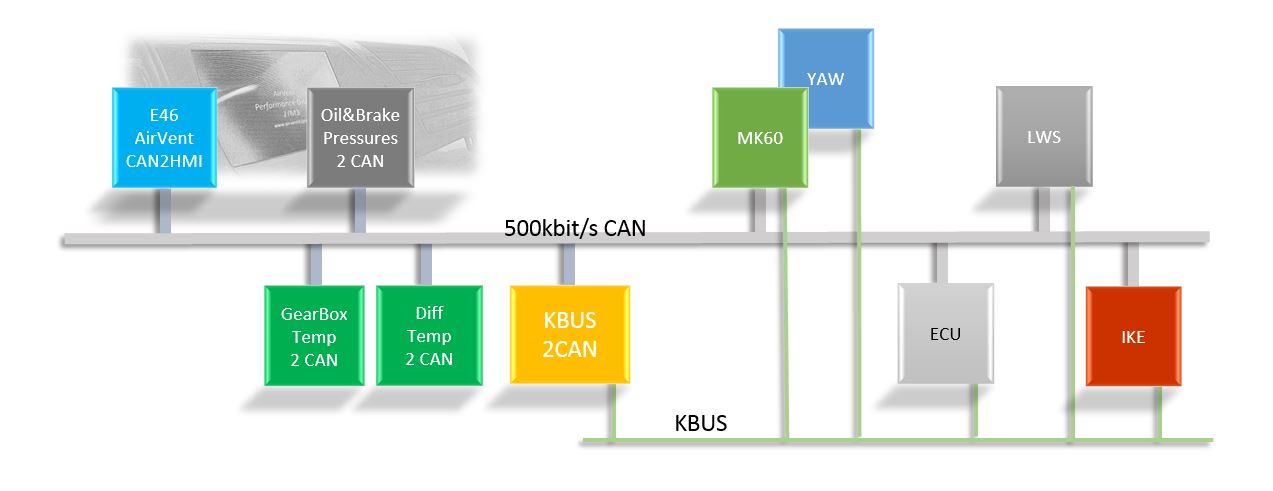

Figure 2: airVent Display, GUI Basic configuration + Options in a Single CAN network

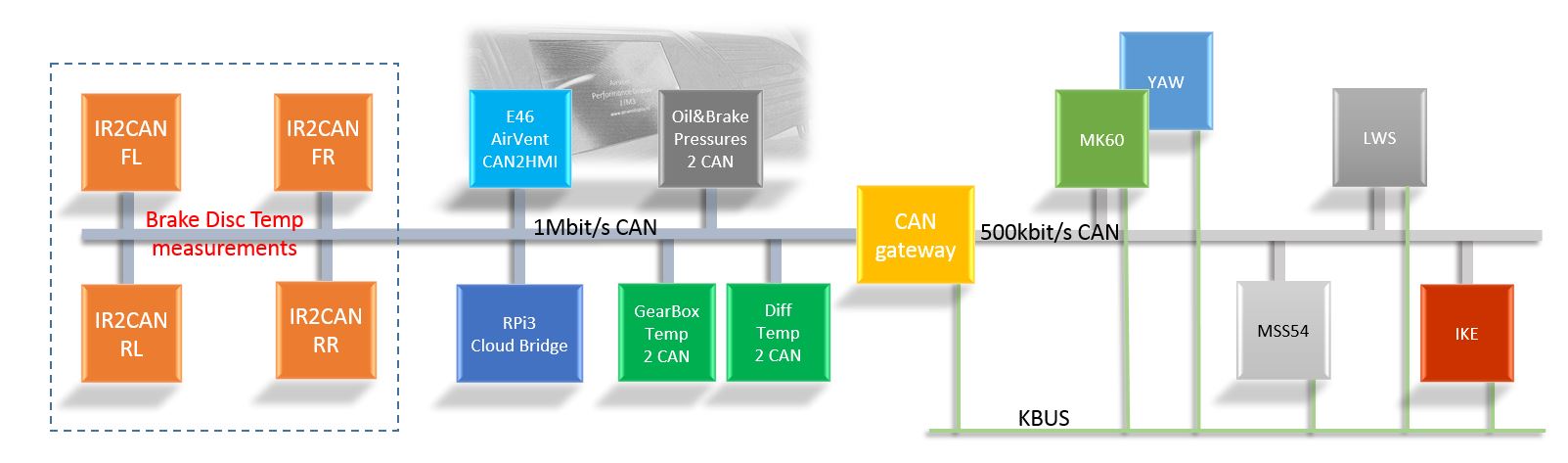

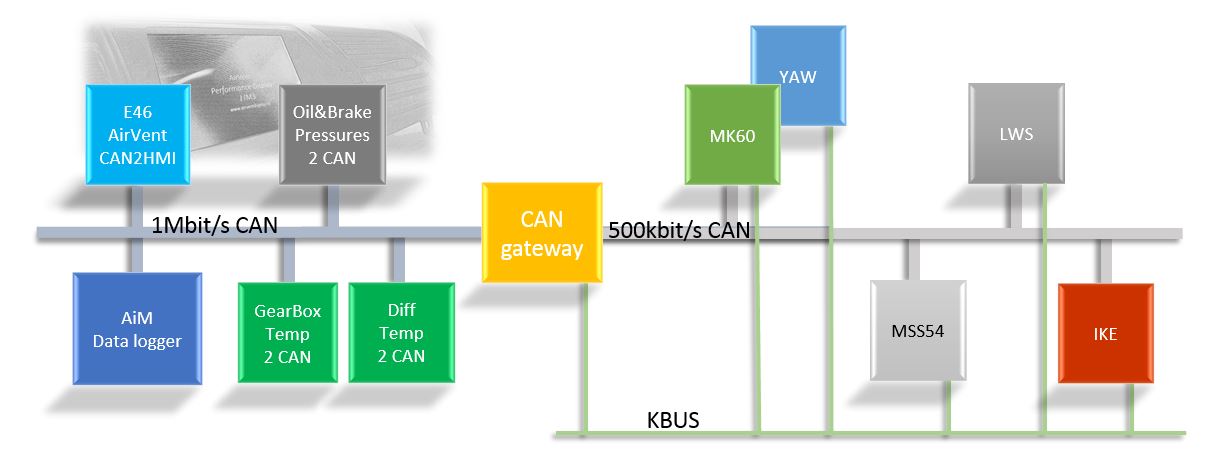

All the optional modules streams their data onto the CAN bus, where the data is subscribed to by the airVent Display system. Since all data is on the CAN bus, the data can easily be picked up by a data logging system. A dual CAN module can be ordered and can be configured as a CAN gateway to convert the CAN data to custom CAN data formats and CAN bus speeds. A simple sketch of such a configuration is shown in Figure 3 below. Motivations to select a dual CAN configuration can be e.g. that one would like to have a system that is 100% decoupled from the E46 CAN bus, or simply that one would like to interface a 1Mbit/s CAN system like e.g. an AiM data logger.

Another motivation, which is one of the main motivations behind the dual CAN solution, is the possibility to stream the CAN data to the cloud using a low cost RaspberryPi3 as a CAN2Cloude Bridge, combined with 4G on a cellphone. This configuration enables a low cost data logging and telemetry solution for track days.

Figure 4: airVent Display, GUI Basic configuration + all Options in a Dual CAN network with RPi3 Cloud Bridge

The track car - which has been used to develop this solution - willl, in addition to the stock E46 CAN data, have data from 3 pressure sensors, 2 temperature sensors and 4 IR brake disc temperature sensors. In order to not disturb the stock E46 CAN bus, as well as account for relatively high measurement frequencies, all the CAN data will be streamed to a separate 1Mbit/s CAN bus.

CUSTOM HARDWARE

Both the hardware and the software is custom made (except the touch display). The hardware is built around the atMEGA328P-AU processor, running at 20Mhz. All interfaces have ESD protection. Power supply is 12V, which is converted to 5V on each module. The software is custom made and optimized with realtime performance in mind. The boot time for the modules is less than 5ms, and hence no "always connected to hot", eleminating discharge of the car's battery. The low boot time also fulfill the boot time requirements for devices connected to the E46 CAN bus.

The HMI is a COTS TFT 3.5" touch display, built around an ARM7 processor running at 108MHz.

INSTALLATION REQUIREMENTS

The installation of the airVent Display system with the GUI Basic software package involves replacing the stock air vent console with the one from airventdisplay.no. The elctrical connections necessary is to attach the airVent Display to +12V, GND, CANH and CANL. Necessarry is also to connect the KBUS2CAN module to +12V, GND, CANH, CANL and KBUS. Additional installation requirements apply for the optional modules.

COMPARISONMENT TO OTHER SOLUTIONS

If the great Internet is correct, there are not that many similar solutions out there. The table below compares the airVent Display (aVD S54) functions with GUI Basic software with the functions found in a comparable solution (solution A).